The principle of pilot solenoid valve is used to control the flow of automatic basic components, belongs to the actuator;It's not limited to hydraulics, pneumatic is used to control the direction of hydraulic flow, the mechanism of the factory are controlled by the hydraulic cylinder, so can use it the working principle of the sealed cavity, open a hole in different locations, each hole leads to different tubing, cavity valve is among, both sides are two electromagnets, which face the magnet coil electricity body will be attracted to which side, by controlling the movement of the valve body blocked or leakage of different discharge of oil hole, and the oil hole is always open, hydraulic fluid will enter the different oil drain, and then through the oil pressure to push oil just the pistons, piston drives the piston rod, piston rod drive mechanism.The mechanical motion is thus controlled by controlling the current of the electromagnet.

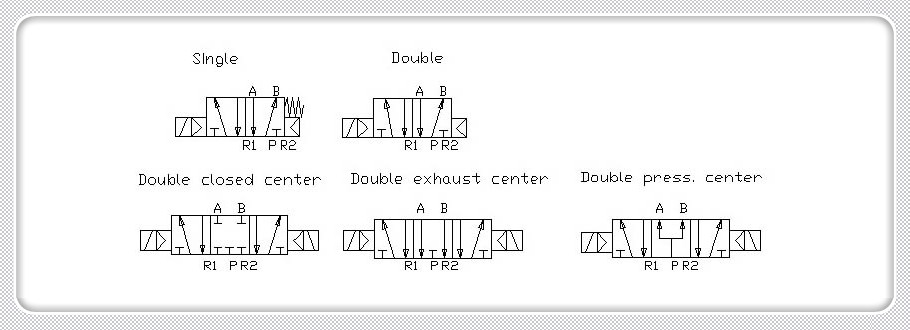

The principle of pilot solenoid valve is used to control the flow of automatic basic components, belongs to the actuator;It's not limited to hydraulics, pneumatic is used to control the direction of hydraulic flow, the mechanism of the factory are controlled by the hydraulic cylinder, so can use it the working principle of the sealed cavity, open a hole in different locations, each hole leads to different tubing, cavity valve is among, both sides are two electromagnets, which face the magnet coil electricity body will be attracted to which side, by controlling the movement of the valve body blocked or leakage of different discharge of oil hole, and the oil hole is always open, hydraulic fluid will enter the different oil drain, and then through the oil pressure to push oil just the pistons, piston drives the piston rod, piston rod drive mechanism.The mechanical motion is thus controlled by controlling the current of the electromagnet.  Principle: when electrified, the electromagnetic force opens the pilot hole, and the pressure in the upper chamber drops rapidly, forming a high and low pressure difference around the closed part. The fluid pressure pushes the closed part to move upward and open.When the power is cut off, the spring force will close the pilot hole, the inlet pressure through the bypass hole rapidly chamber in the valve close around the lower low high pressure difference, fluid pressure to push the closure of parts down, close. Features: high upper limit of fluid pressure range, can be arbitrarily installed (to be customized) but must meet the fluid pressure differential conditions.

Principle: when electrified, the electromagnetic force opens the pilot hole, and the pressure in the upper chamber drops rapidly, forming a high and low pressure difference around the closed part. The fluid pressure pushes the closed part to move upward and open.When the power is cut off, the spring force will close the pilot hole, the inlet pressure through the bypass hole rapidly chamber in the valve close around the lower low high pressure difference, fluid pressure to push the closure of parts down, close. Features: high upper limit of fluid pressure range, can be arbitrarily installed (to be customized) but must meet the fluid pressure differential conditions.| Model | YSVM220 | |

| Fluid | Clean Air | |

| Operating Press. Range | 0.2~0.7Mpa(2 ~7kgf/cm2) | |

| Amb. &Media Temp. | -5~50℃ | |

| Lubrication* | Not Required | |

| Manual Override | Push Button | |

| ShocIWibration | 30G/5G(8.3-2000Hz) | |

| Sealing | Dust Proof | |

| Response Time | 50ms or Less | |

| Eff. Sectional Area mm2(Cv) | 16(0.89)(2 Position) | 12(0.67)(3 Position) | |

| Electric Connection | Grommet(G); DinTerminal(D,DZ) | |

| Rated Voltage | AC110V, 220V(50Hz); DC24V | |

| Allowable Voltage Range | Rated Voltage -15~+10% | |

| Insulation Class | Class Bor Equivalent | |

| Power Consumption | AC | Starting: 5.6VA; Holding: 4.5VA |

| DC | 1.8W/2W With Indication Light | |

| Surge Suppressor | AC: Varistor, DC: Diode | |

| Indication Lamp | AC: Neon, DC: LED | |

| Please Use Tubine Oil 1st-grade ISOVG32#,lf Required | ||