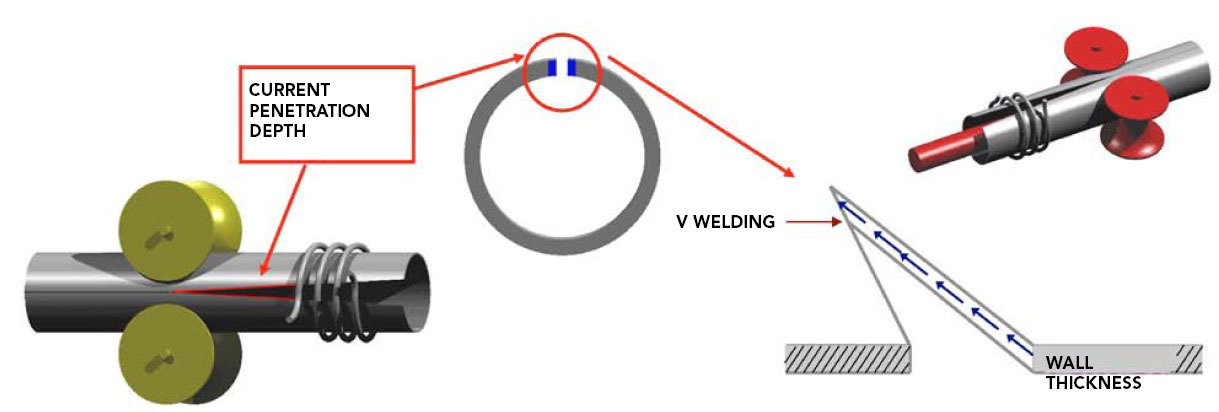

Electricity goes through the working coil. The electric stream is variable and has a high frequency. The electromagnetic induction creates electricity with the same frequency of the electricity present in the inductor. The electricity will concentrate in the surfaces that have to be welded,producing heat, and melt only the superficial parts.

Dimension Eccentricity : <3% Straightness: <0.5:1000mm Supply Condition & Mechanical Properties| Steel Grade | Delivery Condition | Yield Strength | Tensile Strength | Elongation A5 | HRB |

| E355 | +C | ≥580MPa | ≥650MPa | ≥8% | >90 |

| Steel Grade | Standard | C % | Si % | Mn % | P % | S % | Al % |

| E355 | EN10305-2 | 0.14~0.22 | <0.4 | 1.2~1.6 | <0.025 | <0.025 | 0.02~0.07 |

Compare with cold drawing / rolling tube

● Better fine sizes ● Better shape (OD and ID Roundness) ● Improved quality surface (less defect after painting and consequently improved fatigue life) ● Tight Tolerances (Eccentricity and Wall Thickness) à The eccentricity is 3% max instead of 7,5 % as normally guaranteed in Seamless Tubes ● Tubes are safer than seamless à Tubes are controlled 100 % by Ultrasonic Test (Full Body), while seamless are controlled only with Eddy Current

Ex. In USA Market 90% of the cylinders are produced with Welded Tubes, because of availability of welded tubes in the market

As a leading hydraulic cylinder manufacturer, we are committed to providing hydraulic cylinders and solutions to meet the needs of a variety of different market segments. Our products are used in a wide range of applications including mining and construction, agriculture and maintenance, load handling, forestry, lifting, recycling, defense, energy and more.

Different from traditional CD, reaction oil for lubrication to acquire mirror surface ID.

Different from traditional CD, reaction oil for lubrication to acquire mirror surface ID.

We are committed to working with every customer to share ideas and gather critical information about the fit and performance requirements of your specific application of hydraulic cylinders. If our standard line is not suitable for your application, we can advise you on custom hydraulic cylinders and we have extensive experience in designing them. We strive to develop dynamic, innovative and reliable hydraulic and machining solutions that exceed your expectations.