| Bore (mm) | 32 | 40 | 50 | 63 | 80 | 100 | |||||

| Fluid | Clean Air | |||||

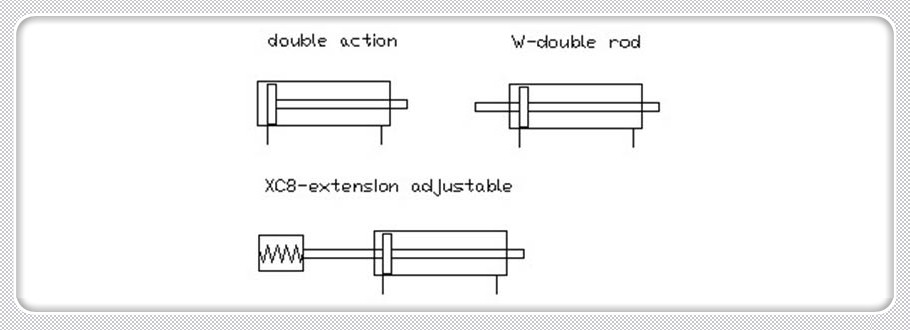

| Action | Double Acting | |||||

| Proof Press. | 1.5Mpa (I5kgf/cm2) | |||||

| Max.Press. | 0.99Mpa (9.9kgf/cm2) | |||||

| Min.Press. | 0.05Mpa (0.5kgf/cm2) | |||||

| Amb. & Media Temp. | 0-60℃ | |||||

| Piston Speed | 50 〜500mm/s | |||||

| Cushion | Air Cushion | |||||

| Stroke Tolerance | -250: 251-1000: 1000-1500: | |||||

| *Lubrication | Lube Type(STD).Non-Lube(Option) | |||||

| Pipe Size RC(PT) | 1/8" | 1/4" | 1/4" | 3/8" | 3/8" | 1/2'' |

| Please Use Turbine Oil ist-grade ISOVG32#.lf Required | ||||||

The following points should be noted in the installation and adaptation of standard cylinders: 1. When the load changes in the work, the cylinder with sufficient output force should be selected; 2. In high temperature or corrosive conditions, the corresponding high temperature or corrosive cylinder should be selected; 3. In the case of high humidity, dust, or water droplets, welding slag, the cylinder shall adopt the protective measures of sigh; 4. Before the cylinder is connected to the pipe, the stolen goods in the pipe must be clear to prevent sundries from entering the cylinder; 5. The medium of 5 cylinders shall be filtered by a filter element above 40um before it can be used; 6. In the low temperature environment, anti-freezing measures should be taken to prevent water freezing in the system; 7. Cylinders should undergo no-load test before use. Before running, the buffer should be adjusted to minimum I and gradually abandoned to avoid damage to the cylinder; In order to maintain the normal operation of the cylinder and extend its service life, the 8 cylinders should avoid lateral load as far as possible in the working process. It is not applicable to remove the cylinder for a long time. Please pay attention to the surface rust prevention and prevent the intake and exhaust from blocking the cap.

The following points should be noted in the installation and adaptation of standard cylinders: 1. When the load changes in the work, the cylinder with sufficient output force should be selected; 2. In high temperature or corrosive conditions, the corresponding high temperature or corrosive cylinder should be selected; 3. In the case of high humidity, dust, or water droplets, welding slag, the cylinder shall adopt the protective measures of sigh; 4. Before the cylinder is connected to the pipe, the stolen goods in the pipe must be clear to prevent sundries from entering the cylinder; 5. The medium of 5 cylinders shall be filtered by a filter element above 40um before it can be used; 6. In the low temperature environment, anti-freezing measures should be taken to prevent water freezing in the system; 7. Cylinders should undergo no-load test before use. Before running, the buffer should be adjusted to minimum I and gradually abandoned to avoid damage to the cylinder; In order to maintain the normal operation of the cylinder and extend its service life, the 8 cylinders should avoid lateral load as far as possible in the working process. It is not applicable to remove the cylinder for a long time. Please pay attention to the surface rust prevention and prevent the intake and exhaust from blocking the cap.